Cold Climate Challenges for Iron Doors

Iron is an excellent conductor of heat—which is precisely the problem in cold climates. Without proper engineering, an iron door becomes a thermal bridge that transfers heat directly from your warm interior to the freezing exterior, driving up energy bills and creating uncomfortable cold spots near your entryway.

The Five Major Cold-Climate Threats

🌡️ Thermal Conductivity

Iron conducts heat 400x faster than wood. Without thermal breaks, your door frame can drop below freezing on the interior side, causing condensation, frost, and ice buildup inside your home.

❄️ Freeze-Thaw Cycles

Water penetrating cracks or finish failures expands when it freezes, creating larger cracks. Northern states experience 50-100+ freeze-thaw cycles per year, accelerating any minor damage.

🧂 Road Salt & De-Icers

Salt tracked in on shoes or splashed from nearby roads is highly corrosive to iron. Calcium chloride de-icers are even more aggressive than traditional rock salt.

🌨️ Snow & Ice Loading

Heavy snow accumulation against doors and ice buildup on thresholds can stress hinges, warp frames, and compromise weatherstripping seals.

Never install a standard iron door designed for mild climates in Minnesota, Michigan, Wisconsin, or other northern states. Doors without thermal breaks and proper insulation will experience condensation, interior frost, and accelerated corrosion—often voiding the manufacturer's warranty entirely.

Why Thermal Breaks Are Non-Negotiable

A thermal break is an insulating barrier built into the door frame that prevents the interior and exterior metal surfaces from directly touching. This interruption in the thermal pathway is the single most important feature for cold-climate iron door performance.

How Thermal Breaks Work

Quality thermal breaks use polyamide (nylon) strips or polyurethane cores that separate the interior and exterior iron components. This creates a thermal barrier with dramatically lower conductivity than solid iron, keeping the interior surface warm even when exterior temperatures plunge below zero.

| Door Type | Interior Surface Temp (0°F Outside) | Condensation Risk | Energy Loss |

|---|---|---|---|

| No Thermal Break | 28-35°F | Severe (frost/ice likely) | Very High |

| Standard Thermal Break | 45-55°F | Moderate | Moderate |

| Premium Thermal Break | 58-65°F | Minimal | Low |

What to Look For

- Polyamide Strips: The industry standard for thermal breaks. Look for strips that are at least 1" wide for northern climates.

- Polyurethane Core: Premium doors feature a foam-injected core in addition to frame thermal breaks, providing superior insulation.

- Complete Separation: Ensure the thermal break extends through the entire frame—including hinges, threshold, and any sidelights.

- Third-Party Testing: Ask for U-factor ratings from NFRC (National Fenestration Rating Council) testing, not just manufacturer claims.

For Minnesota, Michigan, and Wisconsin, insist on a U-factor of 0.30 or lower. Doors meeting ENERGY STAR Northern Zone requirements (U-factor ≤ 0.25) are ideal for the Upper Midwest where winter temperatures regularly drop below -10°F.

Understanding R-Value & Insulation

R-value measures a material's resistance to heat flow—the higher the R-value, the better the insulation. While thermal breaks address the frame, the door panel itself needs proper insulation to prevent heat loss through the door's surface area.

R-Value Comparison for Entry Doors

| Door Type | Typical R-Value | Cold Climate Suitability |

|---|---|---|

| Solid Wood (1¾") | R-2 to R-3 | Poor |

| Steel (no insulation) | R-0 | Not Recommended |

| Steel (polyurethane core) | R-6 to R-8 | Good |

| Fiberglass (foam core) | R-5 to R-7 | Good |

| Iron (foam-injected core) | R-5 to R-8 | Good to Excellent |

| Iron (premium insulated) | R-8 to R-12 | Excellent |

Insulation Options for Iron Doors

Polyurethane Foam Core

The most common option. Foam is injected between interior and exterior iron skins, providing R-6 to R-8 insulation and adding structural rigidity. Ensure foam completely fills all voids.

Polystyrene Core

Less expensive than polyurethane but provides lower R-value (R-4 to R-6). Acceptable for moderate cold climates but not ideal for Upper Midwest winters.

Vacuum Insulated Panels (VIP)

Premium option offering R-25 to R-40 per inch. Rarely found in standard iron doors but available from high-end manufacturers for extreme climate applications.

Multi-Chamber Construction

Some manufacturers use multiple insulated chambers within the door, similar to commercial storefront construction, for exceptional thermal performance.

State-by-State Requirements for Northern Climates

Different northern states present unique challenges based on their specific climate patterns, building codes, and common construction practices. Here's what to consider for the most demanding cold-climate markets.

🏔️ Minnesota

Climate Zone 6-7Key Challenges: Extreme cold (-30°F possible), extended sub-zero periods, heavy snow loads, significant temperature swings between seasons.

Minimum Specs: U-factor ≤ 0.25, thermal break mandatory, R-8+ insulation, triple-pane glass recommended for door lites.

🌲 Michigan

Climate Zone 5-6Key Challenges: Lake-effect snow (extreme accumulation), high humidity in summer followed by dry cold winters, road salt exposure.

Minimum Specs: U-factor ≤ 0.27, thermal break required, corrosion-resistant finish essential for salt exposure.

🧀 Wisconsin

Climate Zone 6Key Challenges: Similar to Minnesota with slightly less extreme lows, significant freeze-thaw cycling, heavy snow loads.

Minimum Specs: U-factor ≤ 0.27, thermal break required, polyurethane foam core minimum R-6.

🦬 North Dakota

Climate Zone 6-7Key Challenges: Extreme cold, high winds (wind chill factor critical), low humidity, rapid temperature changes.

Minimum Specs: U-factor ≤ 0.23, enhanced weatherstripping for wind infiltration, triple glazing highly recommended.

🌾 South Dakota

Climate Zone 5-6Key Challenges: Severe temperature extremes (both hot and cold), high winds, hail exposure, dry climate.

Minimum Specs: U-factor ≤ 0.27, impact-rated glass for hail, robust threshold seals for wind.

🦎 Montana

Climate Zone 6Key Challenges: Extreme cold in northern regions, high altitude in some areas, low humidity, significant UV exposure.

Minimum Specs: U-factor ≤ 0.25, UV-resistant finish, altitude-compensated weatherstripping.

Energy Code Compliance

Most northern states follow the International Energy Conservation Code (IECC), which specifies maximum U-factors for entry doors based on climate zone:

| Climate Zone | IECC 2021 Max U-Factor | Typical States |

|---|---|---|

| Zone 5 | 0.30 | Southern MI, Southern WI, IA, NE |

| Zone 6 | 0.30 | Northern MI, Northern WI, MN, ND, SD, MT |

| Zone 7 | 0.30 | Northern MN, parts of ND, AK |

While code requires U-factor of 0.30 or lower, most energy-conscious northern homeowners opt for U-factor of 0.25 or lower. The additional upfront cost is typically recovered in 3-5 years through energy savings, and provides superior comfort with no cold spots near the entry.

Cold-Climate Glass Options

Iron doors typically feature decorative glass panels, but in cold climates, glass selection becomes critical for thermal performance. The wrong glass can be the weakest link in an otherwise well-insulated door system.

Glass Package Comparison

| Glass Type | U-Factor | Cold Climate Rating | Best For |

|---|---|---|---|

| Single Pane | 1.10 | Not Recommended | Mild climates only |

| Double Pane (clear) | 0.47 | Marginal | Southern Zone 5 |

| Double Pane + Low-E | 0.30 | Acceptable | Zone 5-6 |

| Double Pane + Low-E + Argon | 0.26 | Good | Zone 6 |

| Triple Pane + Low-E + Argon | 0.18-0.22 | Excellent | Zone 6-7 |

| Triple Pane + Low-E + Krypton | 0.15-0.18 | Best Available | Zone 7, Passive House |

Key Glass Features for Cold Climates

- Low-E Coating: Reflects heat back into your home during winter while allowing solar gain. Specify Low-E for northern climates (optimized for cold), not solar control Low-E designed for hot climates.

- Argon or Krypton Fill: Inert gas between panes provides better insulation than air. Krypton offers superior performance but costs more. Both gases dissipate over time (expect 10% loss per decade).

- Warm-Edge Spacers: The spacer between glass panes can be a thermal weak point. Specify warm-edge spacers (stainless steel or structural foam) rather than aluminum.

- Tempered Glass: Code-required for entry doors. Tempered glass is also safer if breakage occurs and handles thermal stress better than annealed glass.

Weatherstripping & Seals for Extreme Cold

Even the most thermally efficient door is only as good as its seals. In cold climates, weatherstripping faces unique challenges: it must remain flexible at sub-zero temperatures, resist ice formation, and maintain compression over thousands of open/close cycles in harsh conditions.

Weatherstripping Types for Cold Climates

EPDM Rubber

Excellent cold-weather flexibility (functional to -40°F). Resists ozone, UV, and aging. The preferred choice for northern climates. Look for closed-cell foam EPDM for best insulation.

Silicone

Superior temperature range (-100°F to +400°F) but more expensive. Excellent longevity and compression recovery. Ideal for extreme northern locations.

Neoprene

Good cold-weather performance to -20°F. Less expensive than silicone but may stiffen in extreme cold. Acceptable for southern portions of climate zones 5-6.

Magnetic Seals

Found on refrigerator-style door systems. Excellent air sealing but less common on decorative iron doors. May be available as an upgrade from premium manufacturers.

Critical Seal Points

- Head & Jamb Seals: Continuous weatherstripping around the door frame is essential. Look for kerf-in or surface-applied seals that compress evenly when the door closes.

- Threshold/Sill: The bottom of the door is most vulnerable to drafts and water intrusion. Specify an adjustable threshold with a compression seal and thermal break.

- Astragal (Double Doors): The seal between two door leaves is often the weakest point. Interlocking astragals with dual weatherstripping provide the best protection.

- Glass-to-Frame Seal: Where decorative glass meets the iron frame requires flexible sealant that won't crack in cold. Silicone-based glazing is preferred.

Vinyl and PVC weatherstripping becomes brittle and cracks below 0°F—avoid these materials in northern states. Also avoid foam tape weatherstripping, which compresses permanently and provides inadequate sealing for entry doors.

Best Finishes for Northern Climates

The finish on your iron door serves as the first line of defense against corrosion. In cold climates, finishes face additional stress from temperature cycling, road salt exposure, and UV damage from snow reflection. Choosing the right finish can mean the difference between decades of beauty and premature failure.

Finish Options Compared

| Finish Type | Cold Climate Durability | Salt Resistance | Maintenance |

|---|---|---|---|

| Powder Coating | Excellent | Excellent | Low |

| Zinc Galvanizing + Paint | Excellent | Excellent | Low |

| E-Coat + Powder Coat | Best | Best | Very Low |

| Oil-Rubbed Bronze | Good | Moderate | Moderate |

| Natural Patina (Living Finish) | Good | Poor | High |

| Paint Only | Fair | Fair | High |

Recommended Finish Systems

- Best Choice - E-Coat + Powder Coat: E-coat (electrocoating) provides a primer layer with excellent adhesion and corrosion resistance, followed by durable powder coat. This automotive-grade process is used on car frames and offers 20+ year protection.

- Excellent Choice - Hot-Dip Galvanizing + Powder Coat: Zinc galvanizing provides sacrificial corrosion protection (zinc corrodes before iron), topped with powder coat for appearance and additional protection.

- Good Choice - Quality Powder Coat: Minimum 3-4 mil thickness with proper surface preparation (sandblasting + primer). Specify TGIC or super-durable polyester powder for UV resistance.

- Use Caution - Oil-Rubbed & Living Finishes: These finishes are beautiful but require regular maintenance and are less resistant to salt damage. Best for covered entries or homeowners committed to seasonal maintenance.

Ask your manufacturer about marine-grade or coastal finish upgrades, even if you're not near the ocean. These enhanced finish systems designed for salt air exposure provide excellent protection against road salt in northern states.

Winter Maintenance Guide for Iron Doors

Proactive maintenance is essential for iron doors in cold climates. A few hours of seasonal care can prevent costly repairs and keep your door operating smoothly through the harshest winters.

Fall Prep (Before Winter)

- Deep Clean: Wash the entire door with mild soap and water, paying special attention to the threshold and bottom rail where salt and debris accumulate.

- Inspect Weatherstripping: Check all seals for cracks, compression set, or gaps. Replace any weatherstripping that doesn't spring back when compressed.

- Lubricate Hardware: Apply silicone-based lubricant (not WD-40) to hinges, locks, and moving parts. Cold temperatures thicken lubricants, so fresh application ensures smooth operation.

- Touch Up Finish: Address any chips or scratches in the finish before winter. Exposed iron will rust rapidly when exposed to salt and moisture.

- Apply Wax Protection: A coat of automotive or marine wax provides an additional barrier against salt and moisture on powder-coated surfaces.

During Winter

- Clear Snow & Ice: Don't let snow or ice accumulate against the door or threshold. Use a plastic shovel or broom to avoid scratching the finish.

- Rinse Salt Regularly: After salt application on nearby sidewalks or driveways, rinse the bottom of the door with clean water when temperatures permit (above 40°F).

- Avoid De-Icer Contact: Keep calcium chloride and other chemical de-icers away from the door. Use sand or cat litter for traction near the entry if possible.

- Check for Condensation: If you notice condensation or frost on the interior of your door, you may have a weatherstripping failure or need to adjust indoor humidity levels.

Spring Recovery

- Thorough Wash: Clean the entire door to remove accumulated salt, sand, and grime. Use a pressure washer on low setting if available, or hand wash with a soft brush.

- Inspect for Damage: Look for rust spots, finish damage, or weatherstripping failures that occurred over winter. Address issues promptly before they worsen.

- Adjust Hardware: Temperature cycling can cause door alignment to shift. Adjust strike plates and hinges if the door doesn't close smoothly.

- Re-Lubricate: Apply fresh lubricant to all moving parts as winter lubricants may have degraded.

Budget approximately $50-100/year for maintenance supplies and 2-3 hours per season for proper care. This small investment can extend your iron door's lifespan by decades compared to neglected doors that require $2,000+ refinishing or replacement.

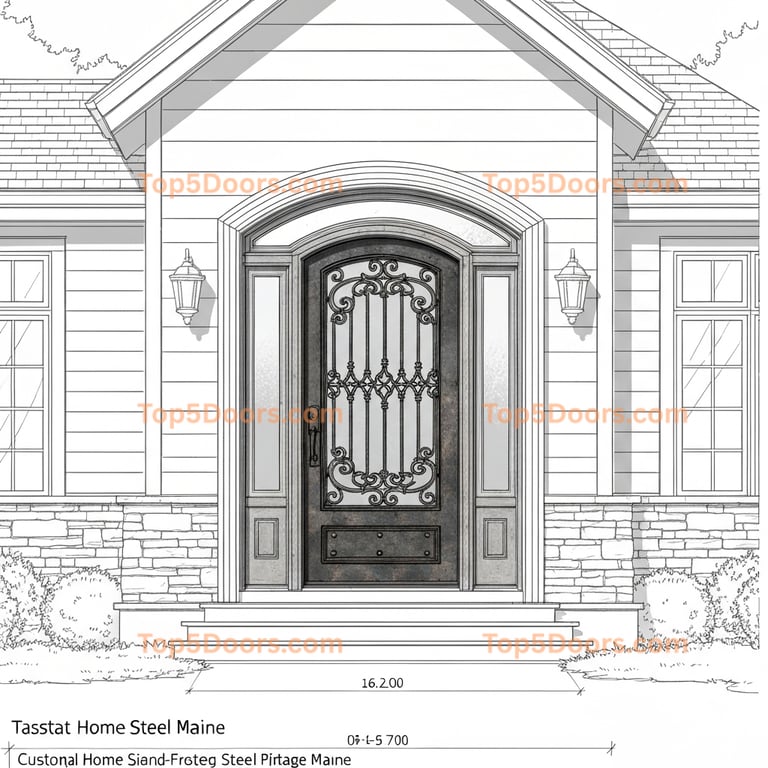

Find Cold-Climate Iron Doors

Browse our gallery of thermally-efficient iron doors designed for northern climates. Save your favorites and request quotes from qualified manufacturers.

Browse Iron Door DesignsChoosing the Right Iron Door for Your Northern Home

Iron doors can perform beautifully in the coldest climates when properly specified. The key is understanding that cold-climate iron doors are fundamentally different from those designed for milder regions—they require thermal breaks, quality insulation, appropriate glass packages, cold-rated weatherstripping, and durable finishes that can withstand decades of freeze-thaw cycles and salt exposure.

Invest in quality from the start: a premium cold-climate iron door may cost 20-30% more than a standard model, but that investment pays dividends in energy savings, comfort, reduced maintenance, and longevity. Cutting corners on thermal performance in Minnesota or Michigan winters is a false economy that will cost far more in heating bills, repairs, and early replacement.

Ready to explore your options? Check out our iron vs. steel comparison guide to understand material differences, or visit our iron door maintenance guide for detailed care instructions. Use our Cost Estimator to budget for your cold-climate door project.