Iron Door Maintenance Overview

Custom iron doors are renowned for their durability, security, and timeless beauty. Unlike wood doors that may need replacement every 20-30 years, a well-maintained iron door can serve your home for a century or more. However, this longevity depends on consistent, proper maintenance.

The good news? Iron door maintenance is straightforward and doesn't require specialized skills. Most tasks take just minutes and use common household supplies. The key is consistency—regular care prevents small issues from becoming major problems.

Time Investment

Expect to spend 15-30 minutes monthly on routine cleaning and inspection. Seasonal maintenance adds another 1-2 hours twice yearly. Most homeowners find this minimal compared to wood door upkeep.

Skill Level Required

Basic maintenance requires no special skills—if you can wash a car, you can maintain an iron door. Only refinishing typically requires professional expertise, and that's needed just once every 10-15 years.

Cost Considerations

Annual maintenance supplies cost $50-150. Professional refinishing runs $800-2,500 every decade or so. Compare this to wood door replacement costs of $3,000-10,000+ every 20-30 years.

Climate Impact

Your climate significantly affects maintenance frequency. Coastal, humid, or extreme temperature areas require more attention than mild, dry climates. We'll cover climate-specific care throughout this guide.

Routine Cleaning & Care

Regular cleaning is the foundation of iron door maintenance. A simple monthly routine prevents dirt buildup, allows early problem detection, and keeps your door looking its best. Here's your complete cleaning guide.

Essential Cleaning Supplies

Soft Cloths

Microfiber or cotton cloths for gentle cleaning

Mild Dish Soap

pH-neutral soap mixed with warm water

Two Buckets

One for soapy water, one for rinsing

Flashlight

For inspecting crevices and scrollwork

Monthly Cleaning Routine

- Dust the entire door surface, including decorative elements and crevices

- Mix a few drops of mild dish soap in warm water (not hot)

- Wash all surfaces with a soft cloth, working from top to bottom

- Clean glass panels with glass cleaner (avoid getting on metal)

- Rinse thoroughly with clean water using a fresh cloth

- Dry completely with a soft, absorbent towel—don't let water pool

- Inspect for any chips, scratches, or early rust spots

- Check weatherstripping for wear or gaps

- Avoid Harsh Chemicals: Never use abrasive cleaners, ammonia, bleach, or acidic solutions on iron doors. These can damage the finish and accelerate corrosion.

- No Pressure Washing: High-pressure water can force moisture into seams and behind weatherstripping, promoting hidden rust. Stick to hand washing.

- Dry Thoroughly: Water left on iron surfaces is the primary cause of rust. Always dry your door completely, paying special attention to horizontal surfaces where water pools.

- Clean After Rain: In addition to monthly cleaning, wipe down your door after heavy rain or storms to prevent water spots and mineral deposits.

The best time to clean your iron door is on an overcast day or when the door is in shade. Direct sunlight causes cleaning solutions to dry too quickly, potentially leaving streaks and reducing cleaning effectiveness.

Preventing & Treating Rust

Rust is the primary enemy of iron doors. Understanding how rust forms and how to prevent it is essential knowledge for any iron door owner. The good news: with proper care, rust should never become a significant problem.

Understanding Rust Formation

Rust (iron oxide) forms when iron reacts with oxygen and moisture. Three factors accelerate rust formation:

Moisture Exposure

Water is essential for rust formation. Standing water, high humidity, and condensation all provide the moisture rust needs to develop. Keeping your door dry is your first line of defense.

Finish Damage

Your door's finish (paint, powder coating, or patina) creates a barrier between iron and moisture. Any scratch, chip, or worn area exposes raw iron to the elements.

Salt & Chemicals

Salt (from coastal air or winter road treatments) and industrial pollutants dramatically accelerate corrosion. These environments require extra vigilance and more frequent cleaning.

Poor Drainage

Water pooling at the door's base—from rain, sprinklers, or poor grading—keeps iron wet longer. Ensure water drains away from your entry and threshold.

Rust Prevention Strategies

- Apply Protective Wax: Automotive paste wax or specialized iron wax creates an additional moisture barrier. Apply annually, or more frequently in harsh climates.

- Address Chips Immediately: Keep manufacturer-matched touch-up paint on hand. Small chips can be touched up in minutes, preventing rust from taking hold.

- Maintain Weatherstripping: Worn weatherstripping allows moisture to reach interior door surfaces. Replace at the first sign of wear.

- Control Sprinklers: Ensure irrigation systems don't spray on your door. Mineral-rich well water is especially damaging.

- Improve Drainage: If water pools near your entry, address the grading or drainage before problems develop.

Inspect your door monthly for these early warning signs: orange or brown discoloration, bubbling or flaking paint, rough texture on previously smooth surfaces, or any visible exposed metal. Early detection and treatment prevents extensive damage.

Treating Minor Rust Spots

If you discover small rust spots, act quickly. Here's how to treat minor surface rust:

- Gently sand the rusted area with fine-grit sandpaper (220-grit) until you reach clean metal

- Wipe away all dust and debris with a tack cloth

- Apply a rust-inhibiting primer to the bare metal

- Let primer dry completely (follow product instructions)

- Apply matching touch-up paint in thin, even coats

- Apply a final coat of protective wax once paint is fully cured

Request rust-inhibiting primer and matching touch-up paint from your door manufacturer at the time of purchase. Having these products on hand ensures you can address chips and scratches immediately, before rust has a chance to develop.

Finish Protection & Refinishing

Your iron door's finish is its primary protection against the elements. Understanding finish types and knowing when refinishing is needed helps you maximize your door's lifespan and maintain its beauty.

Common Iron Door Finishes

| Finish Type | Durability | Maintenance Level | Refinish Interval |

|---|---|---|---|

| Powder Coating | Excellent - most durable option | Low Easy | 15-20 years |

| Liquid Paint | Good - quality varies by product | Moderate | 8-12 years |

| Oil-Rubbed Bronze | Good - develops patina | Moderate Seasonal | 10-15 years |

| Natural Patina | Varies - depends on climate | Higher Annual | Every 5-10 years (sealing) |

| Galvanized + Paint | Excellent - dual protection | Low | 15-25 years |

Annual Finish Protection

- Automotive Wax: Apply high-quality paste wax (like Carnauba) annually. This creates a sacrificial barrier that takes abuse instead of your finish.

- UV Protection: If your door receives direct sunlight, use a wax or sealant with UV inhibitors to prevent fading and finish degradation.

- Industrial Sealants: For harsh environments, consider specialty iron sealants like Everbrite or ProtectaClear that offer enhanced protection.

- Avoid Silicone: Don't use silicone-based products—they can interfere with future refinishing and may cause finish issues.

Signs It's Time to Refinish

Widespread Fading

When the original color has noticeably lightened or changed across large areas, and waxing no longer restores the appearance, refinishing is due.

Chalking Surface

If wiping the door leaves colored residue on your cloth, the finish has degraded to the point of "chalking" and needs replacement.

Multiple Rust Spots

While isolated rust spots can be touched up, multiple spots indicate the finish is failing system-wide and full refinishing is more practical.

Peeling or Bubbling

Visible peeling, bubbling, or flaking of the finish indicates adhesion failure. This requires stripping and complete refinishing.

The Refinishing Process

Professional refinishing typically involves these steps:

- Door is removed from hinges (or refinished in place for very large doors)

- All hardware, glass, and weatherstripping is removed

- Old finish is stripped using media blasting or chemical strippers

- All rust is removed and treated with rust converter

- Door is primed with rust-inhibiting primer

- Multiple coats of finish are applied (paint or powder coating)

- Hardware is cleaned, refinished, or replaced as needed

- Door is reinstalled with new weatherstripping

Budget $800-2,500 for professional refinishing, depending on door size, condition, and finish type. While this sounds significant, compare it to $8,000-20,000+ for a new custom iron door. Proper refinishing extends your door's life by another 10-15 years, making it an excellent value.

Hardware & Moving Parts

Iron doors are heavy—often 200-800+ pounds. This weight places significant demands on hinges, locks, and other moving parts. Regular hardware maintenance ensures smooth operation and prevents costly repairs.

Hinge Maintenance

Lubrication

Apply silicone-based lubricant to hinge pins every 6 months. Avoid petroleum-based products that can attract dirt and gum up over time. Work the door back and forth to distribute lubricant.

Screw Tightening

Check all hinge screws twice yearly. Iron doors' weight can loosen screws over time. Tighten any loose screws immediately to prevent door sagging or misalignment.

Hinge Pin Inspection

Inspect hinge pins for wear annually. Heavy doors accelerate pin wear. Replace worn pins before they cause door dropping or binding.

Ball Bearing Hinges

If your door uses ball bearing hinges, they require less frequent lubrication but should still be checked annually for smooth operation.

Lock & Handle Care

- Lock Lubrication: Apply graphite lubricant to key cylinders annually. Insert key and work it in and out to distribute. Never use oil-based lubricants in locks.

- Multi-Point Lock Systems: These sophisticated locks require annual professional inspection. Ensure all locking points engage smoothly and adjust as needed.

- Handle Tightness: Check handle and lever set screws quarterly. Loose handles can damage internal mechanisms and feel unsatisfying to operate.

- Finish Matching: If hardware finish wears, consider having hardware refinished to match your door's updated appearance after refinishing.

Weatherstripping & Seals

Weatherstripping prevents air infiltration, water intrusion, and pest entry. Iron doors typically use compression seals that should be inspected seasonally:

- Check for visible cracks, tears, or compression set (permanent flattening)

- Close the door and look for daylight around the edges—any visible gaps indicate failed seals

- Feel for drafts around the door perimeter on windy days

- Inspect the threshold seal for wear, especially at high-traffic areas

- Replace weatherstripping at the first sign of failure—don't wait for complete failure

When refinishing your door, consider upgrading to ball bearing hinges if you don't have them already. These self-lubricating hinges handle heavy doors with ease and require minimal maintenance. The investment pays off in smoother operation and longer component life.

Seasonal Maintenance Guide

Different seasons present different challenges for iron door maintenance. Following this seasonal schedule ensures your door receives appropriate care year-round.

| Season | Key Tasks | Time Required |

|---|---|---|

| 🌸 Spring |

|

1-2 Hours |

| ☀️ Summer |

|

30 Min/Month |

| 🍂 Fall |

|

1-2 Hours |

| ❄️ Winter |

|

As Needed |

Climate-Specific Considerations

🌊 Coastal Climates

Salt air accelerates corrosion significantly. Rinse your door with fresh water weekly (or after storms). Apply protective wax every 3-4 months. Inspect for rust monthly.

🌧️ High Humidity Areas

Moisture is your enemy. Ensure excellent drainage around your entry. Consider adding a storm door for extra protection. Apply wax quarterly.

🏜️ Desert Climates

Low humidity is actually favorable for iron, but intense UV causes finish damage. Use UV-protective wax and consider sun-blocking features like extended overhangs.

🌨️ Cold/Snow Belt

De-icing salt is extremely corrosive. Use mats to catch boot residue. Wipe down thresholds frequently. Never use salt-based ice melt on your entry steps.

After any severe weather event—hurricanes, hailstorms, ice storms—inspect your door thoroughly. Impact damage, flooding, or prolonged moisture exposure can cause hidden problems. Document any damage for insurance purposes and address issues immediately.

Professional Maintenance Services

While most iron door maintenance can be handled by homeowners, some tasks benefit from professional expertise. Knowing when to call a pro protects your investment and can prevent costly mistakes.

When to Call a Professional

Extensive Rust Damage

If rust has spread significantly or eaten into the metal, professional treatment is essential. Improper repair can trap moisture and accelerate damage.

Full Refinishing

Complete refinishing requires specialized equipment (media blasters, spray booths) and expertise. DIY attempts often result in poor adhesion and premature failure.

Structural Issues

If your door sags, binds, or won't close properly, this may indicate frame problems or hinge failure requiring professional assessment and repair.

Glass Replacement

Replacing glass panels in iron doors requires precise fitting. Improper installation can crack glass, allow water intrusion, or create security vulnerabilities.

Choosing a Professional

- Start with Your Manufacturer: Many iron door manufacturers offer maintenance services or can recommend approved service providers in your area.

- Look for Specialization: Seek professionals who specifically work with iron doors or ornamental metalwork, not general contractors or painters.

- Request References: Ask for photos of previous iron door work and contact references to verify quality and reliability.

- Get Written Estimates: Detailed written estimates should specify all work to be performed, materials to be used, and warranty provided.

- Verify Insurance: Ensure any contractor working on your home carries appropriate liability and workers' compensation insurance.

Professional Service Costs

| Service | Typical Cost Range | Frequency |

|---|---|---|

| Annual Inspection | $100 - $200 | Annually |

| Minor Rust Treatment | $150 - $400 | As Needed |

| Hardware Adjustment/Repair | $100 - $300 | As Needed |

| Glass Panel Replacement | $200 - $800+ | As Needed |

| Complete Refinishing (Single) | $800 - $1,800 | Every 10-15 years |

| Complete Refinishing (Double) | $1,400 - $2,500 | Every 10-15 years |

| Frame Repair/Realignment | $300 - $800 | Rare |

Some iron door specialists offer annual maintenance agreements that include inspection, cleaning, lubrication, and minor touch-ups for a flat annual fee. These agreements often provide cost savings over individual service calls and ensure consistent professional care.

Maintenance Costs & Budgeting

Understanding the true cost of iron door ownership helps you budget appropriately and appreciate the long-term value. Here's a realistic breakdown of what to expect.

Annual Maintenance Budget

| Expense Category | DIY Approach | Professional Approach |

|---|---|---|

| Cleaning Supplies | $20 - $40 | N/A (included in service) |

| Protective Wax/Sealants | $30 - $60 | N/A (included in service) |

| Touch-Up Paint/Primer | $15 - $40 | N/A (included in service) |

| Hardware Lubricants | $10 - $25 | N/A (included in service) |

| Professional Inspection | $0 (if doing it yourself) | $100 - $200 |

| Annual Total | $75 - $165 | $100 - $200+ |

Long-Term Cost Comparison

When comparing iron doors to alternatives, consider the total cost of ownership over time:

Iron Door (50-Year Cost)

Initial Cost: $8,000 - $15,000

Maintenance: $3,750 - $8,250 (50 years)

Refinishing: $1,600 - $5,000 (2-3 times)

Total: $13,350 - $28,250

Wood Door (50-Year Cost)

Initial Cost: $3,000 - $8,000

Maintenance: $2,500 - $5,000 (higher frequency)

Replacement: $6,000 - $16,000 (2 replacements)

Total: $11,500 - $29,000

Fiberglass Door (50-Year Cost)

Initial Cost: $1,500 - $4,000

Maintenance: $1,250 - $2,500 (lower needs)

Replacement: $3,000 - $8,000 (2 replacements)

Total: $5,750 - $14,500

Value Consideration

While fiberglass appears cheapest, consider that quality iron doors add 5-10% to home value, provide unmatched security, and create irreplaceable curb appeal that cheaper options simply cannot match.

Set aside $150-200 annually in a "door maintenance fund." This covers routine care with a cushion for unexpected repairs. Every 10 years, you'll have accumulated enough to cover professional refinishing without impacting your regular budget.

What to Know Before Buying

Understanding maintenance requirements before purchasing helps you make an informed decision and set realistic expectations. Here are the key factors to consider:

Finish Quality Matters

Invest in the highest quality finish available. Premium powder coating costs more upfront but lasts nearly twice as long as budget finishes, reducing lifetime maintenance costs significantly.

Request Maintenance Kits

When purchasing, ask for a maintenance kit including matching touch-up paint, rust-inhibiting primer, recommended wax/sealant, and detailed care instructions specific to your door's finish.

Understand Your Climate

Be honest about your climate and commitment level. Coastal homeowners should expect more frequent maintenance. If you travel extensively, consider professional maintenance agreements.

Consider Installation Quality

Proper installation is crucial. Poor installation leads to water intrusion, frame problems, and accelerated wear. Always use the manufacturer's recommended installer.

Questions to Ask Your Dealer

- What finish is used, and what's its expected lifespan? Quality dealers should provide specific product information and realistic durability expectations.

- Is the door galvanized before finishing? Galvanization provides an extra layer of corrosion protection under the finish—a significant quality indicator.

- What warranty is provided, and what voids it? Understand exactly what's covered and what maintenance is required to maintain warranty protection.

- Do you offer maintenance services or recommend providers? Manufacturers who stand behind their products typically offer ongoing support.

- What's the estimated refinishing cost and interval? Reputable dealers should provide honest information about long-term maintenance expectations.

Red Flags to Watch For

Be wary of vendors who claim iron doors require "no maintenance," offer unusually low prices without explaining quality differences, cannot provide detailed finish specifications, have no local service network, or offer extremely short warranties (under 5 years). Quality iron doors require care—anyone claiming otherwise is either uninformed or misleading you.

A custom iron door is a multi-generational investment. The maintenance commitment is modest—roughly 15-30 minutes monthly with a few hours seasonally—and the reward is a stunning, secure entrance that will serve your family for 50-100+ years. For homeowners willing to provide consistent basic care, iron doors deliver exceptional long-term value.

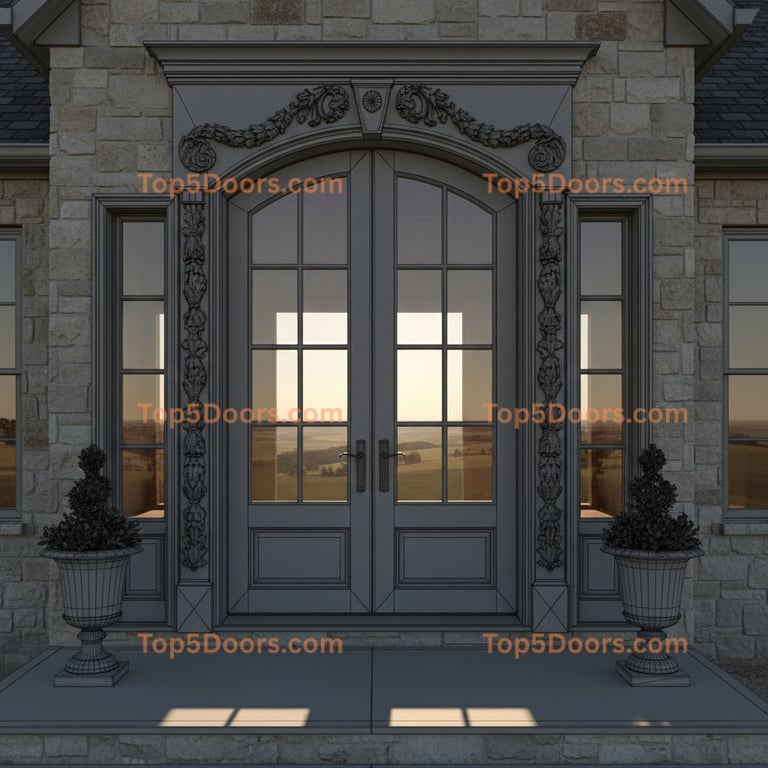

Ready to Find Your Perfect Iron Door?

Browse our curated gallery of custom iron doors to find the perfect entrance for your home. Every door in our gallery represents the craftsmanship and quality that will last generations.

Explore Iron Door GalleryMake an Informed Investment

Custom iron door maintenance is straightforward and manageable for any homeowner willing to invest 15-30 minutes monthly in basic care. The key principles are simple: keep it clean, keep it dry, protect the finish, and address problems early.

With proper maintenance, your iron door investment will provide security, beauty, and value for 50-100+ years—far outlasting any alternative. The maintenance commitment is modest; the reward is a stunning entrance that will serve your family for generations.

Ready to learn more? Visit our Wrought Iron vs. Steel Guide to compare materials, explore our Custom Doors Guide for design options, or use our Cost Estimator to budget for your project.