Why Hot Climates Demand Different Doors

Front doors in hot climate states face a unique combination of stressors that can destroy standard doors within years rather than decades. Understanding these challenges is the first step toward making a smart investment.

🔥 Extreme Heat Exposure

South-facing doors in Texas, Arizona, and Florida can reach surface temperatures exceeding 150°F in direct sunlight. This causes material expansion, warping, finish degradation, and seal failure—often within just a few years.

☀️ Intense UV Radiation

The southern Sun Belt receives up to 50% more UV radiation than northern states. This accelerates fading, chalking, and finish breakdown on doors not specifically designed for high UV exposure.

💨 Thermal Cycling

Daily temperature swings of 30-40°F cause doors to expand and contract repeatedly. Over time, this cycling weakens joints, loosens hardware, and compromises weatherstripping—especially in desert climates.

💧 Humidity Extremes

Florida and Gulf Coast homes face constant high humidity, while Arizona homes deal with monsoon season swings. Both extremes stress door materials and require moisture-resistant construction.

A dark-colored door facing south or west can reach internal temperatures high enough to warp wood, crack glass, and cause catastrophic seal failure. In Phoenix, Las Vegas, and South Texas, door color and material selection are not aesthetic choices—they're engineering decisions that determine whether your door survives or fails.

Best Door Materials for Hot Climates

Not all door materials perform equally under extreme heat. Here's how the major options compare for hot climate homes:

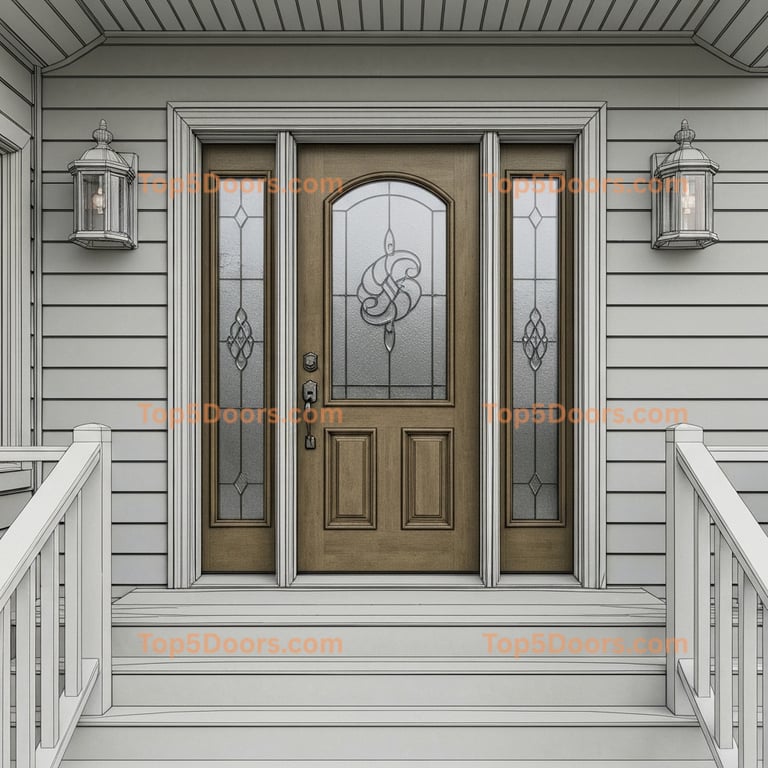

Fiberglass

Best overall for hot climates. Fiberglass doesn't warp, crack, or rot regardless of heat or humidity. It insulates 5x better than wood, resists UV degradation, and can beautifully mimic wood grain. Premium fiberglass doors are the top choice for most hot climate homeowners.

Steel with Thermal Break

Excellent with proper construction. Steel doors with polyurethane foam cores and thermal breaks prevent heat transfer. Galvanized steel with quality powder coating handles heat well. Critical: requires thermal break technology to prevent interior heat transfer.

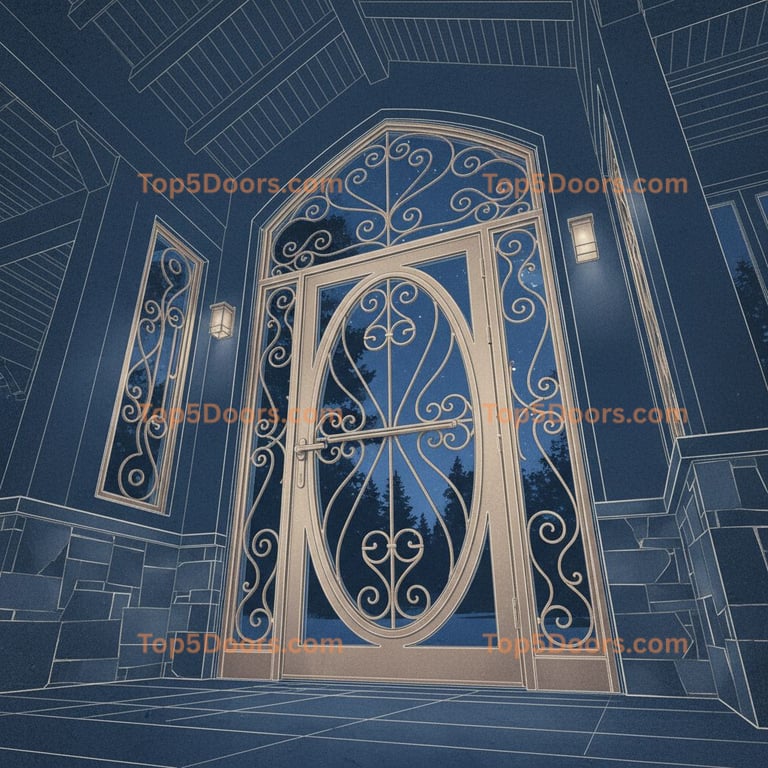

Iron with Thermal Break

Stunning aesthetics meet durability. Quality iron doors with thermal breaks and insulated cores perform beautifully in hot climates. Ideal for Mediterranean, Spanish, and luxury Southwest homes. Requires quality construction with thermal technology.

Wood

Challenging in extreme heat. Even the best hardwoods struggle with hot climate stress. Warping, cracking, and finish failure are common issues. If you must have wood, choose teak or mahogany, apply marine-grade finishes, and ensure the door is protected from direct sun.

| Material | Heat Resistance | UV Resistance | Insulation (R-Value) | Hot Climate Rating |

|---|---|---|---|---|

| Fiberglass | Excellent | Excellent | R-12 to R-15 | |

| Steel (Thermal Break) | Very Good | Good | R-10 to R-15 | |

| Iron (Thermal Break) | Very Good | Good | R-8 to R-12 | |

| Aluminum | Good | Excellent | R-6 to R-10 | |

| Solid Wood | Poor | Poor | R-2 to R-3 |

If your door faces south or west and receives direct afternoon sun, fiberglass is almost always your best choice. Steel and iron with thermal breaks are excellent for protected entries or north/east-facing installations. Reserve wood for fully shaded, covered entries only—and even then, expect more maintenance.

Best Front Doors for Texas Homes

Texas presents diverse climate challenges—from the humid Gulf Coast to the scorching deserts of West Texas and the temperature extremes of the Panhandle. Your door choice should match your specific Texas region.

🤠 Houston & Gulf Coast

- Fiberglass doors with hurricane-rated glass options

- Steel doors with marine-grade finishes and rust protection

- Impact-rated glazing for storm protection

- Moisture-resistant weatherstripping critical

- Consider storm door addition for extra protection

🌵 Austin, Dallas & Central Texas

- Fiberglass with high R-value insulation (R-12+)

- Light to medium colors to reduce heat absorption

- Low-E glass to block solar heat gain

- UV-resistant finishes essential

- Quality weatherstripping for thermal cycling

🏜️ El Paso & West Texas

- Fiberglass doors for superior thermal stability

- Light colors mandatory for sun-exposed entries

- Thermal break construction essential

- Flexible weatherstripping for temperature extremes

- Regular maintenance for dust and UV damage

Top Door Recommendations for Texas

- Primary Recommendation: Fiberglass doors with foam-injected cores provide the best combination of insulation, durability, and UV resistance for the majority of Texas climates.

- Luxury Option: Iron doors with thermal breaks and Low-E glass are popular for Texas Mediterranean and Hill Country homes—ensure quality construction with proper insulation.

- Budget-Friendly: Steel doors with thermal breaks offer excellent value. Look for galvanized steel with polyurethane foam cores and quality powder coating.

- Storm Protection: Gulf Coast homes should prioritize impact-rated glazing and hurricane-rated doors meeting Texas Windstorm Insurance Association standards.

Many Texas homes feature covered porches and deep overhangs that protect front doors from direct sun. If your entry has significant shade coverage, you have more material flexibility. Measure the actual sun exposure at your specific entry before making material decisions.

Best Front Doors for Arizona Homes

Arizona's extreme desert climate—with summer temperatures regularly exceeding 110°F and intense year-round sun—represents perhaps the most demanding environment for front doors in the United States.

🌞 Phoenix Metro

- Fiberglass is the clear winner for sun-exposed entries

- Light colors only for south/west-facing doors

- Low-E glazing blocks 70%+ of solar heat

- R-15+ insulation for maximum energy efficiency

- Flexible seals rated for extreme temperature swings

🏔️ Tucson & Southern Arizona

- Similar recommendations to Phoenix with slight flexibility

- Iron doors viable for shaded courtyards

- Consider higher altitude UV intensity

- Monsoon-ready weatherstripping essential

- Desert-appropriate finishes for dust resistance

🌲 Flagstaff & Northern Arizona

- More material flexibility due to milder climate

- Focus on insulation for cold winters

- Wood doors viable with proper protection

- Still address summer UV exposure

- Snow/ice considerations for thresholds

Critical Arizona Door Features

- Color Selection: In Phoenix, a dark door can reach surface temperatures of 150°F+ in summer. Choose doors with a Light Reflectance Value (LRV) of 40 or higher for any sun-exposed entry.

- Thermal Break Technology: Any metal door must feature thermal break construction to prevent indoor heat transfer. Without thermal breaks, metal doors become radiators that drive up cooling costs.

- Low-E Glass: All glass panels and sidelights should feature Low-E (low-emissivity) coating to block solar heat while maintaining visibility. Look for Solar Heat Gain Coefficient (SHGC) ratings below 0.25.

- Quality Seals: Standard weatherstripping fails in Arizona heat. Specify high-temperature silicone or EPDM rubber seals rated for -40°F to 300°F.

Standard wood doors, especially dark-colored ones, have been documented to warp so severely in Phoenix summers that they become inoperable. We've seen homeowners spend $5,000+ on beautiful wood doors only to replace them within 2-3 years. In Arizona, material selection is not optional—it's essential for door survival.

Best Front Doors for Florida Homes

Florida presents a unique combination of heat, extreme humidity, hurricane threats, and salt air exposure—especially in coastal areas. Your door must handle all these challenges simultaneously.

🌴 South Florida (Miami, Keys)

- Impact-rated doors required in many areas

- Fiberglass with marine-grade hardware

- Hurricane-rated glass (Large Missile Impact)

- Stainless steel hardware for salt resistance

- Verify Florida Building Code compliance

🏠 Central Florida (Orlando, Tampa)

- Fiberglass ideal for humidity resistance

- Consider impact-rated options for storm protection

- Moisture-resistant weatherstripping critical

- Low-E glass for energy efficiency

- Quality ventilation to prevent moisture buildup

🌅 Gulf Coast (Naples, Pensacola)

- Impact-rated doors for hurricane zones

- Marine-grade finishes for salt resistance

- Fiberglass or steel with proper protection

- Upgraded hardware for coastal durability

- Regular maintenance schedule essential

Florida-Specific Door Requirements

- Hurricane Ratings: South Florida (Miami-Dade, Broward, Palm Beach) requires doors meeting High-Velocity Hurricane Zone (HVHZ) standards. Look for Florida Product Approval numbers and Miami-Dade NOA certifications.

- Impact Glass: Impact-rated glazing protects against flying debris during hurricanes. Large Missile Impact rating is required in most of South Florida and recommended throughout the state.

- Salt Air Protection: Coastal homes within 3,000 feet of salt water should specify stainless steel or bronze hardware. Standard steel and iron will corrode rapidly without marine-grade protection.

- Humidity Resistance: Florida's 80-90% humidity levels stress all door materials. Fiberglass excels here; wood and unprotected metal struggle without constant maintenance.

| Florida Requirement | South Florida | Central Florida | Panhandle |

|---|---|---|---|

| Impact Rating Required | Recommended | Recommended | |

| Salt Air Protection | Moderate | High (coastal) | |

| Hurricane Shutters/Protection | Recommended | Required (coastal) | |

| Humidity Resistance | Critical | Critical | High |

When shopping for doors in Florida, always ask for the Florida Product Approval (FL#) number. This confirms the door meets Florida Building Code requirements. In South Florida, also request the Miami-Dade Notice of Acceptance (NOA) for hurricane zone compliance. Doors without these approvals may not pass inspection.

Essential Hot Climate Door Features

Beyond material selection, these features separate doors that thrive in hot climates from those that fail prematurely:

🌡️ Thermal Break Technology

Non-conductive materials separating interior and exterior door surfaces prevent heat transfer. Essential for all metal doors (steel, iron, aluminum) in hot climates. Look for polyurethane or composite thermal breaks—not just foam gaskets.

☀️ Low-E Glass Coating

Low-emissivity glass coatings block 70-80% of solar heat while maintaining clarity. For hot climates, look for SHGC (Solar Heat Gain Coefficient) ratings below 0.30—the lower, the better for cooling efficiency.

🧱 High R-Value Insulation

Door insulation is measured in R-value (higher = better). For hot climates, choose doors with R-12 or higher. Premium fiberglass doors offer R-15 to R-17, rivaling wall insulation values.

🔐 Quality Weatherstripping

Standard weatherstripping fails in extreme heat. Specify silicone, EPDM rubber, or Q-Lon rated for temperature extremes (-40°F to 200°F+). Replace weatherstripping every 3-5 years in hot climates.

Door Color & Heat Absorption

Door color dramatically affects heat absorption, especially for sun-exposed entries. This chart shows surface temperature differences for doors in direct Arizona summer sun:

| Door Color | Light Reflectance Value | Surface Temp (110°F Day) | Hot Climate Rating |

|---|---|---|---|

| White / Cream | 80-90% | 115-125°F | |

| Beige / Tan | 60-75% | 125-135°F | |

| Light Gray / Sage | 45-60% | 130-145°F | |

| Medium Brown / Red | 25-40% | 145-160°F | |

| Dark Brown / Black | 5-20% | 155-175°F+ |

- Thermal break technology for metal doors

- Low-E glass with SHGC below 0.30

- R-value of 12 or higher

- High-temperature weatherstripping (rated 200°F+)

- UV-resistant finish with manufacturer warranty

- Light color for sun-exposed entries (LRV 40+)

- Quality multi-point locking system

- Impact-rated glass for hurricane zones

- Stainless/bronze hardware for coastal areas

- Proper drainage in threshold design

Hot Climate Door Maintenance

Even the best doors require proper maintenance in hot climates. The intense conditions accelerate wear, making regular care essential for longevity.

Monthly Maintenance Tasks

- Visual Inspection: Check for finish cracks, fading, or peeling. In hot climates, UV damage happens faster—address issues before they spread.

- Weatherstripping Check: Heat causes seals to compress and harden. Test for daylight gaps around the door and feel for drafts.

- Hardware Operation: Heat can cause locks and hinges to bind. Apply silicone lubricant monthly rather than annually.

- Glass Seal Inspection: Check for condensation between panes or visible seal failure—common in extreme heat cycling.

Seasonal Maintenance Schedule

| Season | Key Tasks | Focus Areas |

|---|---|---|

| Spring | Deep cleaning, wax application, seal inspection | Prepare for summer heat stress |

| Summer | Weekly cleaning, monthly hardware lubrication | Monitor for heat damage, maintain seals |

| Fall | Refinish touch-ups, weatherstripping replacement | Repair any summer damage |

| Winter | Apply UV-protective sealant, deep clean | Prepare finish for next summer |

Fiberglass Door Care

Clean monthly with mild soap. Apply automotive wax twice yearly for UV protection. Avoid harsh chemicals that strip protective coatings. Touch up any chips immediately to prevent water intrusion.

Steel/Iron Door Care

Clean monthly, dry thoroughly after rain. Wax quarterly in hot climates. Inspect for rust spots monthly—treat immediately with rust converter and touch-up paint. Lubricate all moving parts monthly.

Wood Door Care

Clean monthly with wood-safe cleaners. Re-seal with marine-grade finish every 1-2 years (annually in Arizona). Check for warping after summer heat waves. Keep finish intact to prevent moisture damage.

Glass & Glazing Care

Clean glass monthly with non-ammonia cleaner. Inspect seals quarterly for failure. UV exposure degrades seals faster—budget for reglazing every 10-15 years in hot climates versus 20+ years elsewhere.

In extreme heat areas, perform maintenance early morning or evening—never when the door is hot from sun exposure. Cleaning solutions can flash-dry on hot surfaces, leaving residue. Wax applied to hot surfaces won't bond properly. Wait until the door is cool to the touch before any maintenance work.

How to Choose Your Hot Climate Door

Making the right door choice for your hot climate home requires evaluating your specific situation. Use this decision framework:

Step 1: Assess Sun Exposure

Determine your entry's orientation (N/S/E/W) and measure direct sun hours. South and west entries need maximum heat resistance. North entries have more material flexibility. Shaded entries can consider wood or darker colors.

Step 2: Identify Climate Challenges

List your specific challenges: extreme heat, humidity, hurricanes, salt air. Florida coastal homes prioritize impact ratings and salt resistance. Arizona homes focus on heat and UV. Gulf Coast balances all factors.

Step 3: Set Performance Requirements

Define your minimum standards: R-value (R-12+ recommended), SHGC for glass (below 0.30), impact rating if required, hardware finish for your environment. Don't compromise on these specifications.

Step 4: Consider Aesthetics

Once performance requirements are set, explore style options within those parameters. Modern, traditional, and Mediterranean designs are all available in heat-resistant materials. Match your home's architecture.

Quick Recommendations by Situation

- Sun-exposed Arizona/Nevada entry: Fiberglass in light color, Low-E glass, R-15+ insulation, high-temperature seals

- South Florida coastal home: Impact-rated fiberglass or steel, hurricane-rated glass, stainless hardware, marine-grade finish

- Texas Mediterranean-style home: Iron door with thermal break, Low-E glass, lighter finish, quality powder coating

- Budget-conscious hot climate: Steel door with thermal break, fiberglass skin, foam core, standard Low-E glass

- Shaded/covered entry: More material flexibility—even wood viable with proper finish and maintenance commitment

Questions to Ask Door Suppliers

- What is the door's R-value and how is it measured?

- Does the door feature thermal break construction?

- What SHGC rating does the glass have?

- Is the weatherstripping rated for extreme temperatures?

- What UV protection does the finish provide and what's the warranty?

- Is this door Florida Product Approved/impact-rated (if applicable)?

- What is the recommended maintenance schedule for my climate?

- What warranty coverage applies in extreme heat conditions?

- Can you provide references from customers in similar climates?

- What are the color/finish limitations for sun-exposed installations?

Don't let aesthetics override performance requirements for hot climate installations. A beautiful door that fails in 3 years is no bargain. Start with materials and specifications that will survive your climate, then find designs you love within those parameters. Quality manufacturers offer stunning options in every performance category.

Find Your Perfect Hot Climate Door

Browse our gallery of heat-resistant, energy-efficient door designs perfect for Texas, Arizona, Florida, and other hot climate homes.

Explore Door GalleryMake a Climate-Smart Investment

Choosing the right front door for your hot climate home is one of the most important exterior decisions you'll make. The right door enhances your home's beauty, security, and energy efficiency while lasting for decades. The wrong choice can result in premature failure, ongoing maintenance headaches, and costly replacements.

Key takeaways: Fiberglass is the safest choice for most hot climate installations. Steel and iron with thermal breaks work well with proper specifications. Light colors dramatically reduce heat stress on sun-exposed entries. Quality features like Low-E glass and high R-value insulation pay for themselves in energy savings. And never compromise on hot climate specifications—your door's survival depends on them.

Need more guidance? Explore our front door ideas guide for design inspiration, check our iron door maintenance guide for care tips, or use our Cost Estimator to budget for your project.