The Iron Door Energy Problem

Steel and iron are excellent conductors of heat. Without proper engineering, an iron door creates a thermal bridge—a direct path for heat to escape in winter and enter in summer. Here's why this matters:

What Happens Without Thermal Breaks

❄️ Cold Weather

The interior side of the door becomes extremely cold, causing condensation and frost buildup. The cold radiates into your home, making the entry uncomfortable and forcing your heating system to work harder.

☀️ Hot Weather

The door absorbs sun heat and transfers it inside. Dark finishes can reach 150°F+ on the exterior, turning your entry into a radiator that fights your air conditioning.

💧 Condensation

When interior surfaces fall below the dew point, moisture condenses on and around the door. This can damage finishes, promote mold growth, and create slip hazards.

💸 Energy Bills

Your HVAC system compensates for the heat gain/loss, increasing energy consumption. In extreme climates, a non-thermally broken iron door can add $200-400/year to utility bills.

Thermal Break Technology Explained

A thermal break (also called thermal barrier) is a layer of low-conductivity material inserted between the interior and exterior metal surfaces of a door. This breaks the thermal bridge and dramatically improves energy performance.

How Thermal Breaks Work

Imagine the door frame as a path for heat. Without a thermal break, heat flows directly through the steel from one side to the other. A thermal break inserts a "roadblock"—typically polyamide (nylon) strips or polyurethane foam—that interrupts this flow.

Polyamide Strip Thermal Break

Fiberglass-reinforced nylon strips are inserted into slots cut through the metal frame, physically separating interior and exterior steel.

- Durable and proven technology

- Used in commercial aluminum windows for decades

- 25-35% R-value improvement

- Does not affect structural integrity

Polyurethane Pour & Debridge

Liquid polyurethane is poured into a cavity in the frame, then the metal bridge is machined away, leaving insulating foam connecting interior/exterior profiles.

- Superior thermal performance

- Creates structural bond while insulating

- 40-50% R-value improvement

- More labor-intensive manufacturing

Full Thermal Break Door Panel

The door panel itself contains insulation between inner and outer steel skins, plus thermal break frame technology for complete thermal isolation.

- Best overall thermal performance

- Door + frame are thermally broken

- R-value of 5-8 for door panel

- Premium price: $500-1500 upgrade

Not all "insulated" iron doors have true thermal breaks. Some manufacturers fill door cavities with foam but don't break the frame thermal bridge. Ask specifically: "Is the frame thermally broken?" If they can't explain the technology used, assume it's not truly thermally broken.

Understanding U-Factor & R-Value

Two key metrics measure door energy performance. Understanding these helps you compare products and verify manufacturer claims.

U-Factor (U-Value)

U-Factor measures how much heat passes through a material. Lower is better—a lower U-Factor means less heat transfer.

| U-Factor Range | Performance Level | Suitable For |

|---|---|---|

| 0.50+ | Poor | Mild climates only, not recommended |

| 0.35 - 0.50 | Moderate | Temperate climates (zones 3-4) |

| 0.25 - 0.35 | Good | Most US climates (zones 2-5) |

| 0.20 - 0.25 | Very Good | Cold climates (zones 5-7) |

| Below 0.20 | Excellent | Extreme cold (zones 6-8), passive house |

R-Value

R-Value measures thermal resistance—the inverse of conductance. Higher is better—a higher R-Value means better insulation.

The relationship: R = 1 ÷ U. A door with U-Factor of 0.25 has R-Value of 4.0.

| Door Type | Typical R-Value | U-Factor Equivalent |

|---|---|---|

| Non-insulated iron door | R-1 to R-2 | 0.50 - 1.00 |

| Iron door with foam core only | R-3 to R-4 | 0.25 - 0.33 |

| Thermally broken iron door | R-4 to R-6 | 0.17 - 0.25 |

| Premium thermally broken system | R-6 to R-8 | 0.12 - 0.17 |

| Solid wood door (for comparison) | R-2 to R-3 | 0.33 - 0.50 |

| Insulated fiberglass door | R-5 to R-7 | 0.14 - 0.20 |

Some manufacturers advertise R-Value for just the door panel center, ignoring the frame and glass which typically have lower values. Ask for the whole-unit U-Factor—the rating that includes frame and glazing—to get an accurate picture of performance.

Energy-Efficient Glass Options

Most iron doors feature decorative glass, which is often the weakest thermal link. Choosing the right glass is essential for energy efficiency.

Glass Performance Factors

🔢 Number of Panes

Dual-pane (insulated) glass is minimum for energy efficiency. Triple-pane provides even better performance but adds weight and cost.

💨 Gas Fill

Argon or krypton gas between panes insulates better than air. Argon is cost-effective; krypton performs better but costs significantly more.

🌡️ Low-E Coating

Low-emissivity coatings reflect heat radiation. Different Low-E types optimize for heating climates (reflect heat in) vs. cooling climates (reflect heat out).

📐 Spacer System

The spacer between glass panes can be aluminum (cheaper, conducts heat) or warm-edge (better thermal performance, reduces condensation).

Glass Recommendations by Climate

| Climate | Recommended Glass | Key Specifications |

|---|---|---|

| Northern/Cold (Zones 5-8) | Triple-pane or dual-pane with high-gain Low-E | U-Factor ≤0.30, SHGC ≥0.40 |

| Moderate (Zones 3-4) | Dual-pane with moderate Low-E | U-Factor ≤0.35, SHGC 0.30-0.40 |

| Southern/Hot (Zones 1-2) | Dual-pane with low-gain Low-E and tint | U-Factor ≤0.40, SHGC ≤0.25 |

| Mixed (heating & cooling) | Dual-pane with balanced Low-E | U-Factor ≤0.32, SHGC 0.25-0.35 |

SHGC (Solar Heat Gain Coefficient) measures how much solar radiation passes through glass. Lower SHGC blocks more heat—good for cooling climates. Higher SHGC lets heat in—good for heating climates.

Weatherstripping & Air Sealing

Even the best thermally broken door loses efficiency if air leaks around it. Quality weatherstripping is essential for maintaining the thermal envelope.

Weatherstrip Types for Iron Doors

- Compression Bulb Seals: Rubber or silicone bulbs that compress when the door closes. Standard on quality iron doors. Should compress 25-50% when door is closed for optimal seal.

- Magnetic Seals: Used on steel doors to create a refrigerator-like seal. Excellent air sealing but adds cost. Works only with properly aligned steel surfaces.

- Brush Seals: Fine brush strips at the bottom of the door or in the astragal (meeting stile on double doors). Allow door movement while blocking drafts.

- Adjustable Thresholds: Allow fine-tuning of the bottom seal. Critical for iron doors which may settle differently than the original framing.

- Interlocking Astragals: On double doors, an overlapping design where one door's edge fits into a channel on the other, blocking direct air paths.

Signs of Poor Sealing

🌬️ Visible Daylight

With door closed, if you see daylight around edges, air is flowing freely. This is an installation problem or worn weatherstripping.

🍃 Paper Test

Slide paper between door and frame and close. If paper slides freely, the seal isn't compressing. Good seal grips paper firmly.

💨 Candle/Smoke Test

Hold a candle near door edges on a windy day. Flickering indicates air leaks that are letting conditioned air escape.

🌡️ Thermal Camera

IR cameras show temperature differences clearly. Cold spots around door edges indicate infiltration points that need attention.

Weatherstripping is a wear item. Even quality seals degrade over 5-10 years from UV exposure, compression set, and door movement. Budget for replacement seals as part of long-term maintenance.

Recommendations by Climate Zone

Energy requirements vary dramatically by location. Here's what to prioritize based on your IECC climate zone:

Zones 1-2 (Hot Climates)

Primary concern is keeping heat OUT. Focus on solar heat gain reduction and air sealing.

- Thermal break frame required

- Low-SHGC glass (≤0.25)

- Light-colored exterior finish

- U-Factor ≤0.40 acceptable

Zones 3-4 (Mixed Climates)

Balance of heating and cooling needs. Moderate thermal performance with versatile glass.

- Thermal break strongly recommended

- Balanced Low-E glass

- U-Factor ≤0.35

- SHGC 0.25-0.40 depending on orientation

Zones 5-8 (Cold Climates)

Primary concern is keeping heat IN. Maximum insulation with solar heat gain where beneficial.

- Premium thermal break essential

- Triple-pane or high-gain Low-E glass

- U-Factor ≤0.25 (lower for zone 7-8)

- SHGC ≥0.40 for south-facing

For detailed cold climate recommendations, see our Best Iron Doors for Cold Climates guide. For hot climates, check our Hot Climate Door Guide.

Calculating Your Energy Savings

How much will an energy-efficient iron door actually save? The answer depends on your climate, energy costs, and what door you're replacing.

Estimated Annual Savings

| Upgrade Scenario | Cold Climate | Moderate Climate | Hot Climate |

|---|---|---|---|

| Old wood door → Thermal break iron | $150-250/year | $80-150/year | $60-120/year |

| Non-thermal iron → Thermal break iron | $200-350/year | $100-200/year | $75-150/year |

| Standard iron → Premium thermal system | $75-150/year | $40-80/year | $30-60/year |

These estimates assume average US energy costs (~$0.15/kWh electric, $1.50/therm gas). Your actual savings will vary based on local rates, home insulation, door size, and usage patterns.

Payback Period

The thermal break upgrade typically adds $500-1,500 to an iron door's cost. At $150-250/year savings in cold climates, the payback period is 3-8 years. In moderate climates, expect 5-12 years. The door will provide decades of savings beyond payback.

Energy savings are measurable, but comfort improvements are equally valuable. A thermally broken door eliminates cold drafts in winter and hot radiant surfaces in summer, making your entry area comfortable year-round—something that doesn't show up in utility calculations but significantly improves daily life.

ENERGY STAR & Tax Credits

ENERGY STAR certification and federal tax credits can offset the cost of energy-efficient doors—but the requirements and benefits have specific limitations.

ENERGY STAR Requirements

The EPA's ENERGY STAR program certifies doors that meet regional performance criteria:

| Climate Zone | U-Factor Requirement | SHGC Requirement |

|---|---|---|

| Northern (zones 6-8) | ≤0.21 | Any |

| North-Central (zones 4-5) | ≤0.25 | Any |

| South-Central (zone 3) | ≤0.30 | ≤0.25 |

| Southern (zones 1-2) | ≤0.40 | ≤0.25 |

Federal Tax Credits (2023-2032)

Under the Inflation Reduction Act, qualifying exterior doors may be eligible for tax credits:

- Credit Amount: 30% of product cost up to $250 per door, maximum $500 total for all doors annually.

- Requirements: Must meet ENERGY STAR Most Efficient criteria for your climate zone.

- Installation Costs: The credit applies to product cost only, not installation labor.

- Documentation: Keep Manufacturer's Certification Statement and purchase receipts for tax filing.

Few iron door manufacturers have pursued ENERGY STAR certification due to the niche market. If tax credits are important to you, verify ENERGY STAR certification BEFORE ordering. Most iron doors can meet the technical requirements but may lack the official certification documentation needed for tax credit claims.

Energy Efficiency Checklist

Use this checklist when evaluating iron doors for energy performance:

Frame & Door Panel

- ☐ Thermal Break Frame: Confirm polyamide strip or polyurethane pour thermal break technology

- ☐ Insulated Door Panel: Foam-filled door panel with thermal separation between skins

- ☐ Whole-Unit U-Factor: Get U-Factor rating for complete assembly (not just door center)

- ☐ Climate Appropriate: U-Factor meets ENERGY STAR requirements for your zone

Glass & Glazing

- ☐ Insulated Glass: Dual-pane minimum, triple-pane for cold climates

- ☐ Gas Fill: Argon or krypton gas fill between panes

- ☐ Low-E Coating: Appropriate Low-E coating for your climate (high-gain or low-gain)

- ☐ Warm-Edge Spacer: Non-metallic spacer system to reduce edge condensation

Sealing & Installation

- ☐ Quality Weatherstripping: Compression seals on all four sides

- ☐ Adjustable Threshold: Allows fine-tuning of bottom seal

- ☐ Professional Installation: Certified installer with thermal break experience

- ☐ Foam Sealing: Installation includes foam sealing between frame and rough opening

Documentation

- ☐ NFRC Label: National Fenestration Rating Council certified performance data

- ☐ ENERGY STAR (if needed): Certification for tax credit eligibility

- ☐ Written Specifications: Detailed spec sheet with all thermal values

- ☐ Warranty Coverage: Confirm seal and thermal break warranty terms

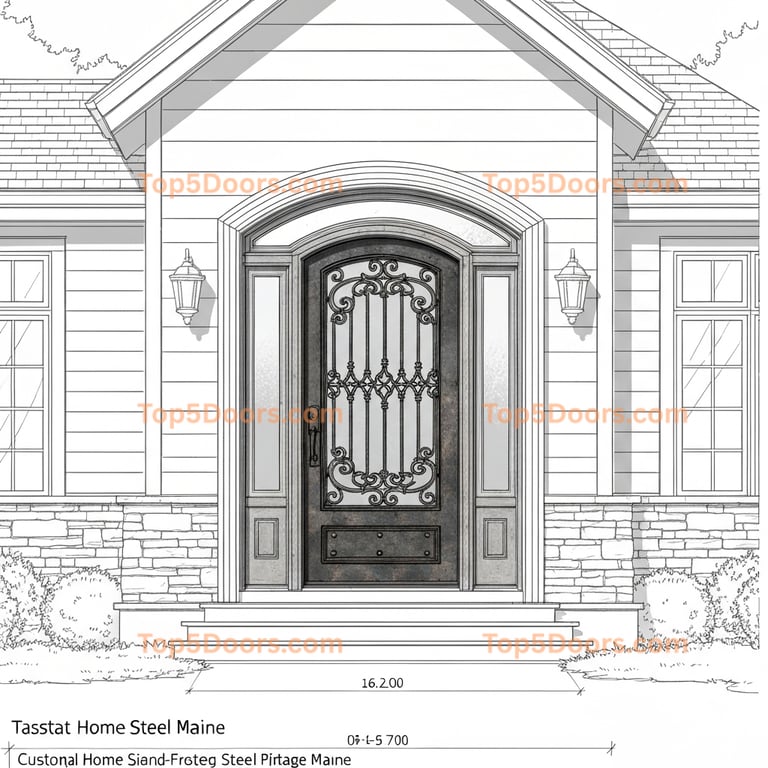

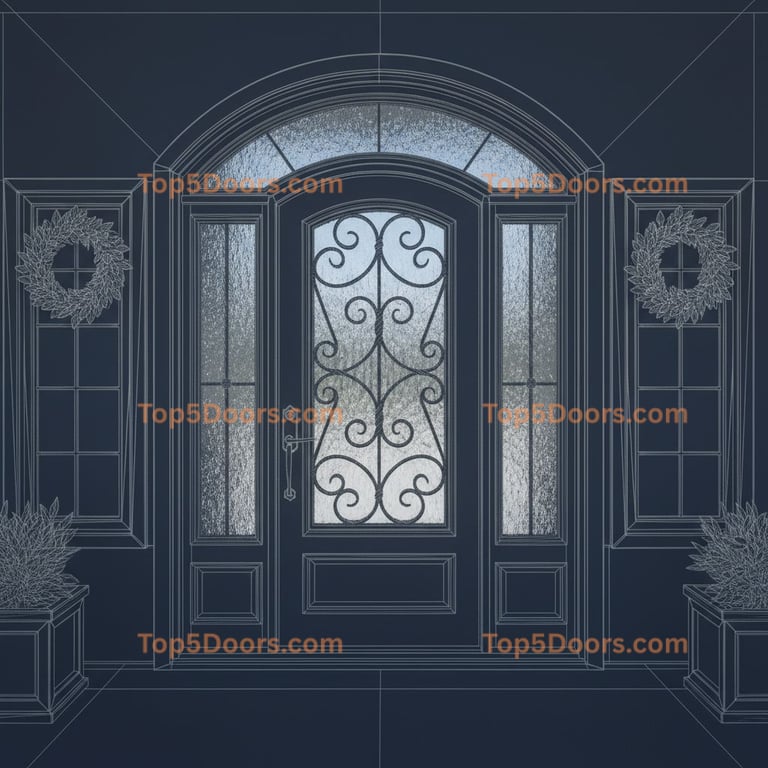

Find Energy-Efficient Iron Door Designs

Browse our gallery of iron entry doors that combine timeless aesthetics with modern thermal performance.

Explore Iron Door Gallery →